Leistung Nachfrage Kontrolle |

Power Demand Control System The energy challenge facing the world is real. Most country continues to experience electrical shortages and rolling blackouts throughout the world. To reduce the risk of power outages, the most important thing we can do in the short term is reduce our demand for electricity and use energy more efficiently. Saving the energy, it will also help saving the world from bad environmental and pollution.

How can control the power demand How can The Demand Controller System save the electricity cost? What happen if we calculate on the average of kW in every 15(or 3) minutes!

Demand can be controlled by cutting on the highest spice of power usage. So we can monitor the way that the power is consumed. We can manage it. If we can move this task to other time, we can save the power. We can calculate the demand by average kW in every 15 minutes (Red line) and the maximum average will be the maximum demand in the month. So if demand is very high we can reduce by 5 ways.

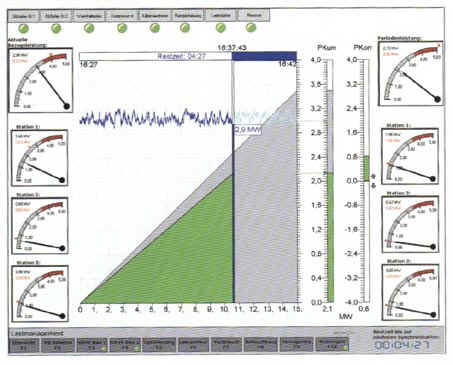

Controller and software From the figure, if show electrical consumption in 15 minutes. There are 3 lines in the figure

1. Blue line shows electrical consumption 2. Green line shows demand, average of kW in 15 (or 3)minutes 3. Read line shows control line, control demand not over the maximum

If demand line is higher than the control line, it means electrical consumption is very high and trends to be higher than we expected. And if we reduce electrical consumption, the demand line will be lower than the control line. And, it need to do immediately or within 15 minutes. Namely system nucleus software is for the advanced software of "analysis of trend ", The computer will get data from power meter, kW and kWh, at the incoming of the transformer by using RS-422/485 interface card. Then the computer will calculate demand from every load in every second and compare with set up data. The computer will transfer the result to PLC to control load by cutting or connecting load.

Reason of using Programmable Logic Control (PLC). 1. PLC is reliable and factory type of equipment 2. PLC can be programmed, and perform more complicated function. 3. PLC can be monitored and control remotely from management office with a maximum of 1,200 Meters. |

Power Quality & Systemen

Power Quality & Systemen